Full Automatic Drinking Carbonated Beverage Sparkling Soda Water Soft Drink Filling Machine

Products Description

This MCGX series washing filling capping mono block is used in the production all kinds of carbonated drink contained in PET bottle. Washing, filling and capping are integrated into one machine, The machine design scientific, beautiful appearance, complete function, convenient maintenance and high automation.

Features

(1) The suspending bottle-neck cramping design make the whole production line more stable during the working process and it also avoids malfunctions caused by the differences of thickness and height of the bottle. This design also dramatically reduces the required number of changeable parts,makes it more convenient to change the types of bottle.

(2) The advanced technologies from Germany and Italy are introduced.Isobaric filling technology is used in this machine.Filling is quick and the amount of the liquid can be controlled accurately.Also.the beverage-holding tank is full-closed and the CIP interface is installed.

(3) Magnetic torque is used for screw capping, and the power of screw capping can be adjusted steplessly. Capping is reliable and do no harm to the caps.

(4) Horizontal swirl wind-power cap-managing device is used to avoid damaging the surface of the cap.And when there is shortage of caps in the caps storage tank,caps will be fed automatically.

(5) Advanced technologies, such as human-machine interface touch-screen and PLC program control are adopted in this machine.

(6) All parts that have direct contact with the beverages are made of high quality stainless steel. The critical electrical components are from famous international companies, such as Mitsubishi, Omron to name a few.

Choose your production output per hour:

MCGX-2K Bottle Water Washing Filling Capping Machine, 1000-2000 bottles per hour.

MCGX-3K Bottle Water Washing Filling Capping Machine, 2000-3000 bottles per hour.

MCGX-5K Bottle Water Washing Filling Capping Machine, 4000-5000 bottles per hour.

MCGX-8K Bottle Water Washing Filling Capping Machine, 6000-8000 bottles per hour.

MCGX-10K Bottle Water Washing Filling Capping Machine, 8000-10000 bottles per hour.

MCGX-12K Bottle Water Washing Filling Capping Machine, 10000-12000 bottles per hour.

MCGX-15K Bottle Water Washing Filling Capping Machine, 13000-15000 bottles per hour.

Main Technical Parameters

| Item | MCGX-2K | MCGX-3K | MCGX-5K | MCGX-8K | MCGX-10K | MCGX-12K |

| Production Capacity (bottles/per hour) | 1000-2000 | 2000-3000 | 4000-5000 | 6000-8000 | 8000-10000 | 10000-12000 |

| Filling Pressure (Map) | ≤0.4 |

| Bottle Type | Bottle Diameter: 50-100mm Height: 150-320mm Volume: 330-1500ml |

| Cap Shape | Plastic Screw Cap |

| Gas Source Pressure(Mpa) | 0.6 |

| Gas Consumption | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 |

| Washing head | 8 | 14 | 18 | 24 | 32 | 32 |

| Filling head | 8 | 12 | 18 | 24 | 32 | 32 |

| Capping head | 3 | 5 | 6 | 8 | 8 | 10 |

| Main motor power (KW) | 3.2 | 4.6 | 5.4 | 6.4 | 8.5 | 11 |

| Total Weight (KG) | 2000 | 2600 | 3500 | 5200 | 6500 | 8000 |

| Packing size (mm) | 2200*1200*2000 | 2450*1650*2100 | 2600*1800*2100 | 3000*2200*2400 | 4000*2200*2400 | 4100*2700*2600 |

Choose or customize the bottles you want:

Details Images

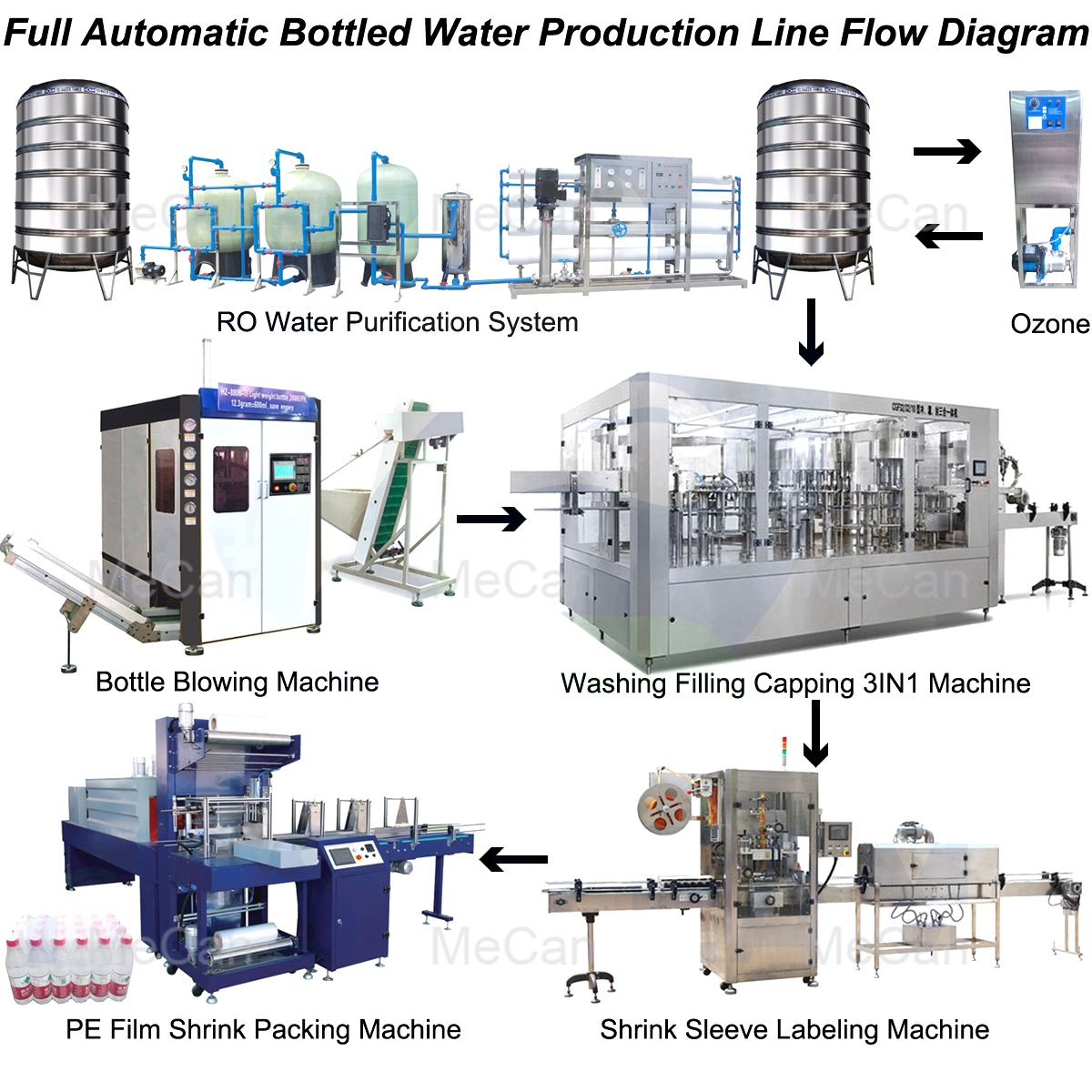

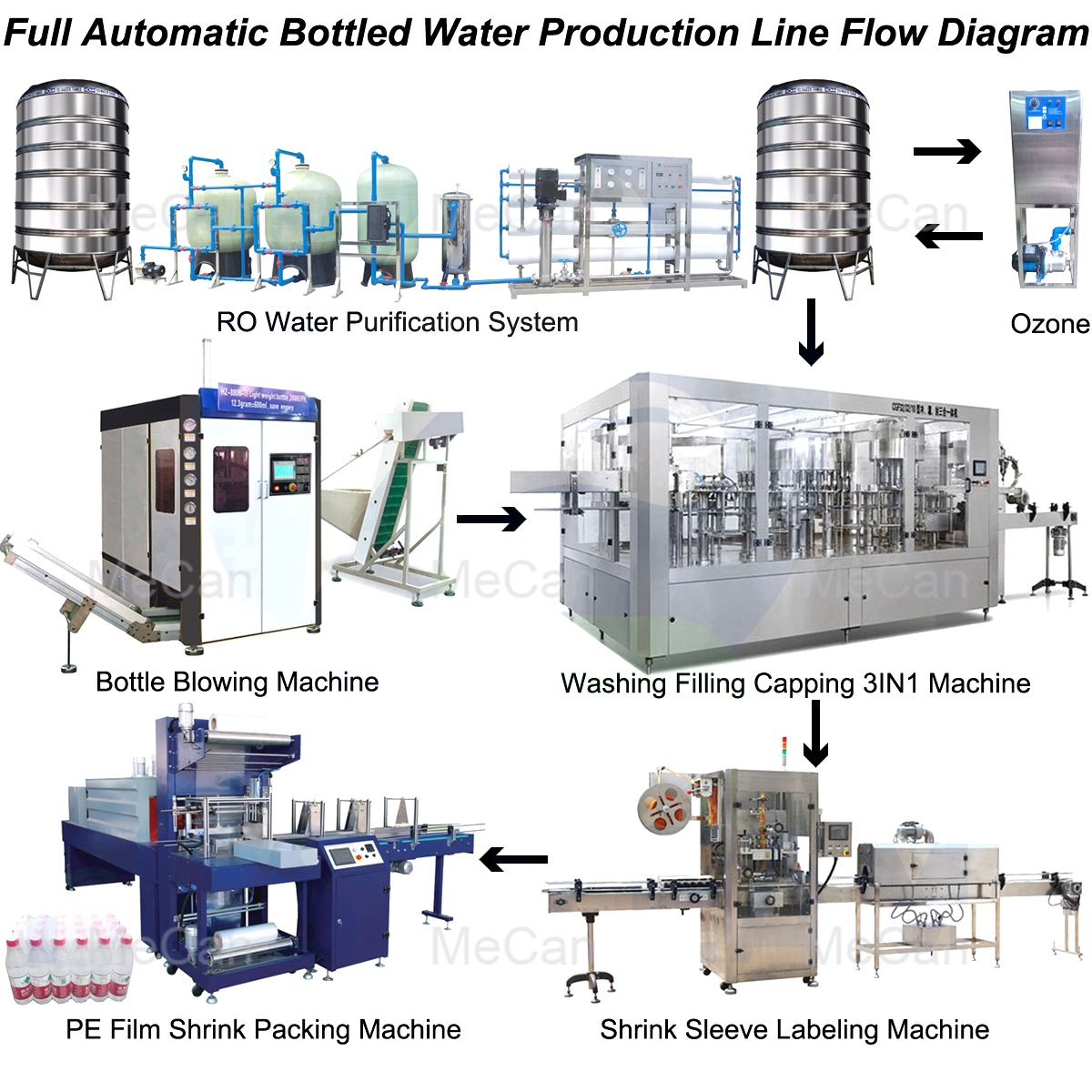

Other Water Production Line:

Showroom of our RO Machine:

Company Advantages

MeCan provide one-stop solutions for new hospitals, clinics, labs and universities, has helped 270 hospitals, 540 clinics,190 vet clinics to set up in Malaysia, Africa, Europe, etc. we can save your time, energy and money. More than 20000 customers choose MeCan. MeCan Focus on medical equipments over 15 years since 2006.

Frequently Asked Questions about

Q: What is your warranty for the products?

A: More than 12 months for free

Q: What is your lead time of the products?

A: 40% of our products is in stock, 50% of the products need 3-10 days to produce, 10% of the products need 15-30 days to produce.

Q: Quality Control (QC)

A: we have a professional quality control team to ensure that the final pass rate is 100%.

Q: What is your payment term?

A: Our payment term is Telegraphic Transfer in advance, Western union, MoneyGram, Paypal, Trade Assurance,ect.

Q: What is your after-sales service?

A: We provide technical support through operating manual and video, Once you have questions, you can get our engineer's prompt response by email,phone call, or training in factory. If it's hardware problem, within the warranty period, we will send you spare parts for free, or you send it back then we repair for you freely.